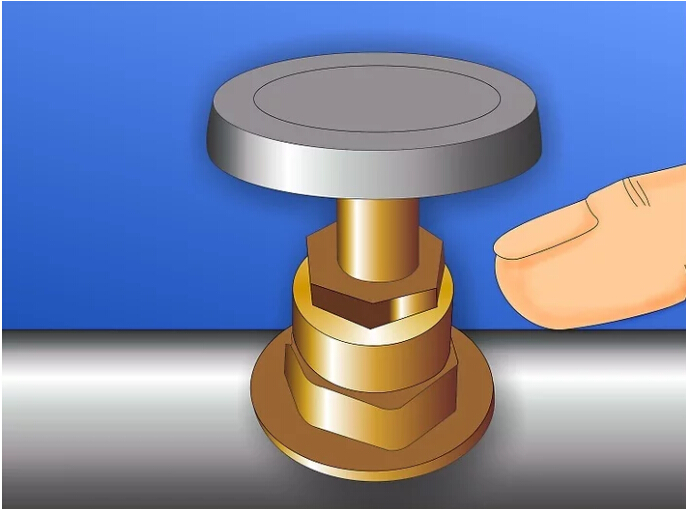

The sanitary butterfly valve has a disc around the valve shaft, which realizes the opening and closing of the valve in a closed component of the main pipe. The opening and closing parts of the butterfly valve is located on the disc-shaped valve plate around its own axis, so as to achieve the purpose of opening, closing or regulating. The butterfly valve is fully open to full closure, usually less than 90 degrees. The butterfly valve and the butterfly rod are not self-locking in themselves, so that they can be placed on the disc on the worm wheel mounted on the stem. The use of worm gear reducer can not only make the disc with self-locking ability stop at any position, but also improve the operation performance of the valve.

Sanitary butterfly valves are characterized by high-temperature resistance, high-pressure range, large nominal valve size, carbon steel valve body, valve plate sealing ring using the metal ring instead of the rubber ring. Large and high-temperature butterfly valves are manufactured by steel plate welding. They are mainly used for the high-temperature medium of flue gas duct and gas pipeline.

In the 1930s, the United States invented the butterfly valve, which has been introduced into Japan in the 1950s, and widely used in the 1960s. In general, the sanitary butterfly valve of DN300 mm has gradually replaced the gate valve. It has a short opening and closing time, small operating torque, lightweight and small installation space. For DN1000 butterfly valve is easy to combine with a variety of actuators, with good durability and reliability.

The disadvantage of sanitary butterfly valves with rubber seals is that cavitation will occur when the valve is used improperly for throttling, causing rubber seats to spall and damage. To this end, the international community has now developed metal-sealed butterfly valves, cavitation area has declined in recent years, Japan in recent years also developed cavitation, low vibration, low noise resistance comb butterfly valve.

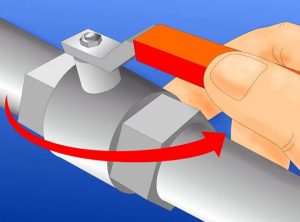

Basically, the relationship between valve opening and flow change is linearly proportional. If used to control flow, flow characteristics and pipe flow resistance are also closely related, such as the installation of two pipe valve, so the overall form is same, and pipe loss coefficient from the valve flow difference will be huge.

If the throttle state of the valve is significantly reduced and cavitation is prone to occur on the back, the valve may be damaged, usually at 15 degrees outside.

When the sanitary valve is open, an opening shape centered on the valve shaft is formed at the front end of the valve body and the disc, forming on both sides to complete a different state, moving along the flow direction of the front end on one side of the disc, moving in the direction of countercurrent water on the other side, thus forming a nozzle-like opening on one side of the valve body and the disc, similar to a hole. On the other side of the V-shaped opening part, the flow rate of the nozzle side is faster than the throttle side.

Operating torque of butterfly valve actuator, due to the opening and closing valve parts are in different directions. Horizontal butterfly valve, especially large diameter valve, due to the depth of water, the valve shaft, torque changes caused by the water level difference cannot be ignored. In addition, the inlet side of the valve is bent to form a bias current, and the torque will increase.