Electric regulating valve installation and application of considerations

Electric control valve, according to the different mediums, the valve body material also has a different choice, commonly used carbon steel, corrosive choice of stainless steel 304 or 316, 316L, and other materials can also choose fluorine lined control valve. There are several types of electric control valves: low-temperature control valves, high-temperature control valves, high-pressure control valves, small-flow control valves, and so on.

Improper use of the regulating valve device is caused by, such as the installation environment, improper installation orientation, direction not the clean pipeline, and other reasons caused. Electric control valve installation and use to pay attention to the following aspects.

(1) electric control valve is classified as a field appearance, requiring the ambient temperature should be -25 ~ 60 ℃ scale, relative humidity ≤ 95%. Is the installation of open-air or high-temperature occasions, should adopt waterproof, cooling methods. There is a source of vibration party to stay away from the source of vibration or add anti-vibration methods.

(2) sanitary regulating valve should generally be installed straight, but in special cases can be skewed, such as a skewed point of view very large valve own weight is too large for the valve should add support pieces to protect it.

(3) installation of the control valve pipeline generally does not leave the face or plate too high, the pipeline height is greater than 2m should try to set up channels to facilitate the operation of the hand wheel and facilitate the repair.

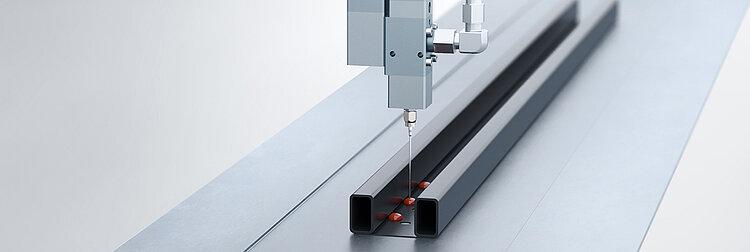

(4) electric regulating valve installation should be cleaned before the pipeline to exclude dirt and welding slag. After installation, in order to ensure that no impurities remain in the valve, the valve should also be cleaned again, that is, when passing into the medium should make all valves open to avoid impurities stuck. After using the handwheel organization, should be rehabilitated to the original neutral position.

How to operate the control valve?

How to operate the electric regulating valve: motor work, through the gear work, by the three connectors of the sliding rheostat output valve positioning signal, in addition to the three lines of the limit signal.

Electric control valve operation principle: motor power 220VAC or 380VAC, control signal 4~20mA, there is a controller inside the valve, the controller converts the current signal into the angular stroke signal of the stepper motor, the motor rolls, and the gear, lever, or gear plus lever, drives the valve stem to operate and complete the straight stroke or angular stroke.

How should the electric control valve be installed?

The temperature sensor can be installed in any position and the entire length must be immersed in the controlled medium. The electric control valve generally contains a driver, bearing the driver signal (0-10V or 4-20MA) to control the valve for adjustment, but also according to the control needs, the composition of the intelligent network control system, optimal control to complete remote monitoring.