How to Select Check Valves?

1, in order to prevent the media backflow, check valves should be installed on equipment, devices, and pipelines.

2, check valve is generally suitable for clean media, should not be used for containing solid particles and viscosity of the media.

3, generally in the nominal through 50mm of the horizontal pipeline should be selected vertical lift check valve.

4, a straight-through lift check valve can be installed on both horizontal and vertical pipelines.

5, for the pump inlet pipeline, it is appropriate to use the bottom valve, the bottom valve is generally installed only on the vertical pipeline of the pump inlet, and the medium flows from the bottom up.

6, lift type swing type good sealing, fluid resistance, horizontal should be installed in the horizontal pipeline, vertically installed in the vertical pipeline.

7, swing check valve installation location is not restricted, it can be installed in the horizontal, vertical, or inclined pipeline, such as installed in the vertical pipeline, the media flow direction from the bottom up.

8, the swing check valve should not be made into a small diameter valve, can be made into a very high working pressure, PN can reach 42MPa, and DN can also be very large, relatively large can reach more than 2000mm. According to the shell and seal material can be applied to any working medium and any working temperature range. The medium is water, steam, gas, corrosive medium, oil, medicine, etc. Medium working temperature range between -196–800℃.

9, the applicable occasion is a low-pressure large diameter, and the installation occasion is restricted.

10, butterfly check valve installation position is not restricted, can be installed in the horizontal pipeline, can also be installed in the vertical or inclined pipeline.

11, the diaphragm check valve is suitable for easy to produce water strikes on the pipeline, the diaphragm can well eliminate the water strikes generated by the media backflow, it is generally used in low-pressure room temperature pipeline, especially suitable for water pipelines, the general medium working temperature between -12 – 120 ℃, working pressure <1.6MPa, but the diaphragm check valve can be larger caliber, DN larger can reach 2000mm or more

What is the function of the check valve?

A check valve is a valve that relies on the flow of the medium itself and automatically opens and closes the valve flap to prevent the backflow of the medium, also known as a check valve, check valve, backflow valve, and back pressure valve.

Sanitary check valve belongs to a kind of automatic valve, its main role is to prevent the backflow of the medium, to prevent the pump and drive motor reversal, as well as the release of the container medium.

Check valves can also be used to provide recharge to auxiliary systems in which the pressure may rise above the system pressure. Check valves can be mainly divided into swing check valves (rotating according to the center of gravity) and lift check valves (moving along the axis).

The clamp check valve is also known as the backflow valve, or the back pressure valve. These valves are automatically opened and closed by the force generated by the flow of the medium itself in the pipeline, and belong to an automatic valve.

First, the use of the check valve is installed in the pipeline system, its main role is to prevent the backflow of media, check valve is an automatic valve relying on the pressure of the medium to open and close. The clamp check valve is suitable for nominal pressure PN1.0MPa ~ 42.0MPa, Class150 ~ 25000, nominal diameter DN15 ~ 1200mm, NPS1/2 ~ 48, working temperature -196 ~ 540 ℃ of various pipelines, used to prevent the backflow of media. By choosing different materials, it can be applied to a variety of media such as water, steam, oil, nitric acid, acetic acid, strong oxidizing medium, and uric acid.

Second, the main materials of the clamped check valve are carbon steel, low-temperature steel, duplex steel (F51/F55), titanium alloy, aluminum bronze, Inconel (INCONEL), SS304, SS304L, SS316, SS316L, chrome molybdenum steel, Monel (400/500), 20# alloy, Hastelloy and other metal materials.

Third, the standards and specifications of the clamped check valve

1、Design and manufacture: API594, API6D, JB/T89372

Structure length: API594, API6D, DIN3202, JB/T89373

Pressure and temperature grade: ANSI B16.34, DIN2401, GB/T9124, HG20604, HG20625, SH3406, JB/T744

Test and inspection: API598, JB/T90925

With pipe flange: JB/T74~90, GB/T9112-9124, HG20592~20635, SH3406, ANSI B 16.5, DIN2543-2548, GB/T13402, API605, ASMEB16.47

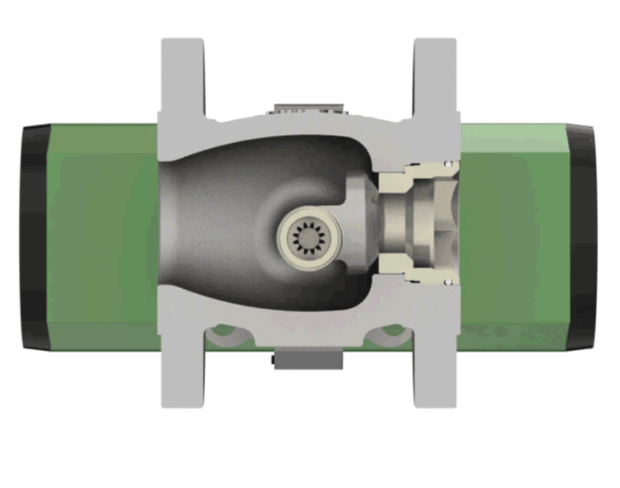

Fourth, the structural characteristics of the butt check valve

1, short structure length, its structure length is only 1/4~1/8 of the traditional flange check valve

2, small volume, light weight, its weight is only 1/4~1/20 of the traditional flange check valve

3、The valve flap closes quickly and the water hammer pressure is small

4, horizontal or vertical pipeline can be used, easy to install

5, smooth flow channel, small fluid resistance

6、Sensitive action, good sealing performance

7、Short stroke of valve flap, small closing impact

8, simple and compact overall structure, beautiful shape

9、Long service life, reliable performance