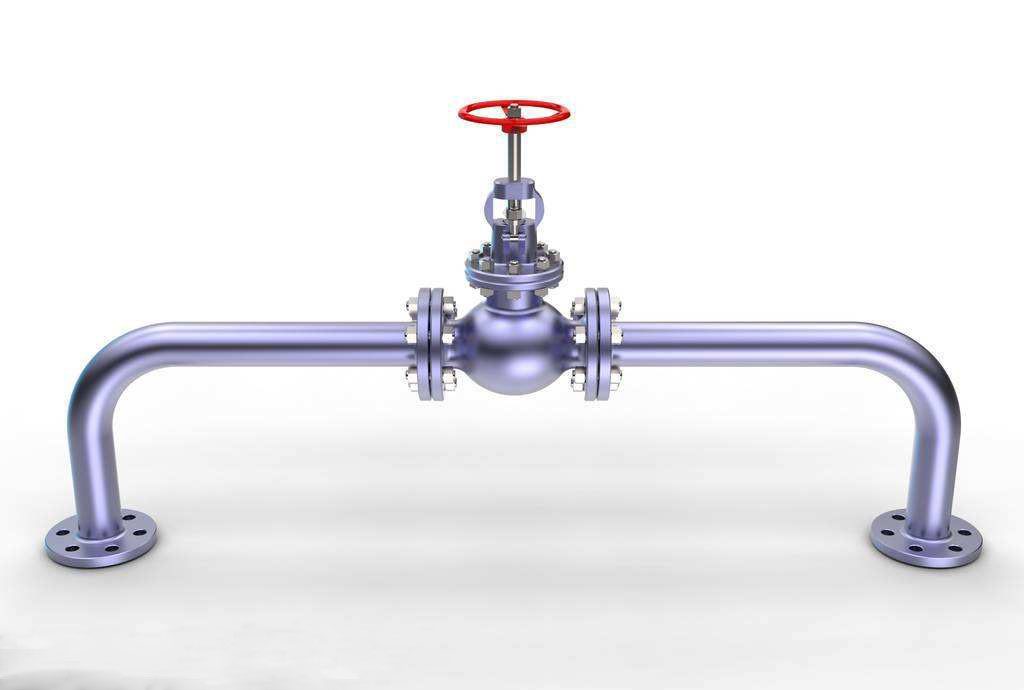

Sanitary ball valve is the most widely used among all of the sanitary valves. The ball valve has the action of rotating 90 degrees. The cock body is a sphere with a circular through-hole or passage passing through its axis. Ball valves are primarily used in the pipeline to intercept, distribute and change the direction of movement of the medium, it only needs to rotate 90 degrees of operation and a small rolling moment, it can be closed tightly. Ball valves are most suitable for switching and blocking valves.

Sanitary ball valve can be divided into carbon steel ball valve, stainless steel 304 ball valve, 316 ball valve and copper ball valve and a cast iron ball valve. It widely used in petroleum, chemical, power generation and other sectors, is made of stainless steel as raw materials, stainless steel ball valve commodities have strong anti-corrosion characteristics, simple structure, tight and reliable features.

Seven advantages of ball valves:

1, The fluid resistance is small, and the drag coefficient is equal to the length of the pipe.

2. The structure is simple, small and light.

3. Strict and reliable, now the ball valve sealing surface information widely used plastic, good sealing, in the vacuum system has also been widely used;

4, Convenient operation, opening and closing agile, from full to full clearance only need to rotate 90 degrees to facilitate remote control.

5, Its repairing process is convenient, the ball valve structure is simple, the seal ring is usually active, and the replacement is convenient.

6. When the ball and the valve seat are fully open or closed, the sealing surface is separated from the medium, and the medium will not cause the erosion of the valve sealing surface after the period of time.

7. Ball valves have a wide range of applications, ranging from small to several millimeters in diameter to 1.2 meters in diameter, and can be used from high vacuum to high pressure.

The seven advantages of sanitary ball valves make it the most widely used valve in the profession.

Classification and precautions of ball valves

Ball valves are: floating ball valve, fixed ball valve, trackball valve, V-ball valve, three-way ball valve, stainless steel ball valve, forged steel ball valve, ash ball valve, sulfur ball valve, pneumatic ball valve, electric ball valve, jacketed ball valve, welding ball valve.

According to the shell / main material classification, the ball valves can be divided into:

1. Metal valve: such as carbon steel valve, alloy steel valve, stainless steel valve, cast iron valve, titanium alloy valve, Monel valve, copper alloy valve, aluminum alloy valve, lead alloy valve, etc.

2. Metal body lined valves: such as rubber-lined valves, fluorine-lined valves, lead-lined valves, plastic-lined valves, enamel-lined valves.

3. Non-metallic materials valves: ceramic valves, glass valves, plastic valves.

They can be divided into threaded ball valves, flanged ball valves and plate ball valves.

Attentions in using ball valve:

(1) It is necessary to ascertain that the pressure of the upper and lower flow pipes of the ball valve has been removed before the dismantling and differentiation operation can be carried out.

(2) After cleaning, non-metallic parts should be removed immediately from the cleaning agent and not soaked in long term.

(3) Bolts on flanges should be tightened symmetrically, gradually and evenly.

(4) The cleaner should be compatible with rubber, plastic, metal and working medium (such as gas) in the ball valve. When the working medium is gas, gasoline can be used to clean metal parts. Nonmetal parts are cleaned with pure water or alcohol.

(5) Every single ball valve can be cleaned by immersion. Metallic parts with undifferentiated non-metallic parts can be wiped with clean, neat silk cloth impregnated with detergent. When cleaning, remove all grease, dirt, glue, dust and so on, which are adhered to the wall.

(6) It is necessary to take care to avoid damaging the sealing surface of parts, especially non-metallic parts, when ball valves are divided and re-installed. Special tools should be used when removing O-rings.

(7) After cleaning, it needs to be installed after the wall cleaner evaporates, but it must not be placed for a long time, otherwise, it will rust and be polluted by dust.

(8) New parts should also be cleaned before installation.

(9) Smooth grease. Smooth grease should be compatible with metal, rubber parts, plastic parts and operating media of ball valves. When the working medium is gas, it can be used, for example, special 221 smooth greases. A thin layer of smooth grease is coated on the surface of the groove of the sealing device, a thin layer of smooth grease is coated on the rubber seal, and a thin layer of smooth grease is coated on the sealing surface of the valve stem and the conflicting surface.

(10) No metal debris, fibers, grease, dust, other impurities, foreign bodies, etc. It shall be allowed to contaminate, adhere to or remain on the surface of the parts or enter the inner cavity.

For more information, please visit http://www.adamantvalves.com/