What is sanitary diaphragm valve?

The sanitary diaphragm valve adopts clamp type, quick-install type and screw type, which has the advantages of simple structure, beautiful appearance, quick assembly and disassembly, quick switch, flexible operation and small fluid resistance, and its opening and closing piece is made of soft material , The valve body cavity and the valve cover cavity and drive components separated from the use of safe, suitable for chemical, petroleum, metallurgy, water heating, food, pharmaceutical and other industries water, gas, oil and corrosive media control.

What are the classifications of sanitary diaphragm valve?

Hygienic diaphragm valve can be divided into six types: house type, DC type, cut-off type, straight type, gate type and right angle type. The connection type is usually flange connection. According to the driving mode, it can be divided into manual, electric and pneumatic Three, including pneumatic drive is divided into normally open, normally closed and reciprocating three. General should not be used for temperatures higher than 60 degrees and the transport of organic solvents and strong oxidizing medium in the pipeline, it should not be in the higher pressure piping.

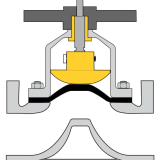

Features: a prominent feature is the diaphragm to the lower valve body cavity and the upper cover cavity separated from the diaphragm at the top of the stem, disc and other parts from the media corrosion, eliminating the need for packing seal structure, and will not produce media leak.

The use of rubber or plastic and other soft sealing diaphragm produced, better sealing. Since the diaphragm is a wearing part, it should be replaced periodically depending on the characteristics of the medium.

Limited by the diaphragm material, diaphragm valve for low pressure and temperature is relatively high occasions.

Hygienic diaphragm valve can be divided into six types: house type, DC type, cut-off type, straight type, gate type and right angle type. The connection type is usually flange connection. According to the driving mode, it can be divided into manual, electric and pneumatic.

The general valve should not be used for temperatures higher than 60 degrees and the transport of organic solvents and strong oxidizing media in the pipeline, but also not used in the higher pressure piping.