Sanitary ball valve test preparation

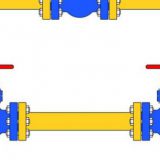

1) The test valve is in the partially open position. Open the water supply valve, the cut-off valve, the exhaust valve and the cut-off valve is filled the system with air and remove the air: the system closes the cut-off valve. The test valve is closed and the shut-off valve is opened. The system is pressurized with water at a pressure of 1.1 times the maximum allowable working pressure at a test width of 20 degrees. Check the test system for leaks, if any, should be eliminated.

2) If the sanitary check valve of the inlet valve seal is also sealed, then, when the valve is closed, it should be measured in the valve cavity in the amount of water, and record the value. If the water accumulated in the middle chamber of the valve flows into the metering container 20 through the outlet side seal subassembly during the refractory test, the amount of water is subtracted from the total amount of water collected by the metering container 20 in determining the amount of leakage through the valve seal pair.

The function and requirement of sanitary ball valve test system

1) The role of the steam pipe is to test the valve inlet cooling liquid to minimize the role.

2) The accuracy of the pressure gauge is not less than 1.5. The measured pressure value should be within 30% to 70% of the measuring range.

3) The temperature measuring block is made of carbon steel, its size as shown in Figure 2-32. The thermocouple is placed in the center of the temperature measuring block. The connecting thread of the temperature measuring block is according to GB / T 7306 “55. For test valves of nominal size DN “150 mm, two temperature-measuring blocks shall be provided. For test valves of nominal size DN> 150 mm, three temperature-measuring blocks shall be provided.

4) Thermocouples are used for temperature measurement. The minimum reading for thermocouples should be less than or equal to 1 degree.

5) The dimensions of the metering vessel shall be appropriate to facilitate the collection and measurement of the medium leaking through the test valve during the test.

6) The water level gauge is used to measure the amount of water used during the test.

7) A pressure relief valve connected to the test chamber of the sanitary valve pressure relief valve is used to prevent the build-up of liquid in the chamber of the test valve from cracking the valve body due to vaporization.

The setting pressure of the pressure relief valve is 1.5 times of the maximum allowable working pressure at 20 degrees of the test valve.