One thing individuals will frequently dismiss when experiencing the procedure of tagging a pump for a clean application is the thing that to do after they get the pump on location. In all actuality, there are a few decent funneling practices that ought to be remembered when planning your next framework that will help amplify pump administration life and rate of return. This post will concentrate on great clean pump funneling practices and things you ought to remember for your next sterile PD pump introduce.

Straight Lengths

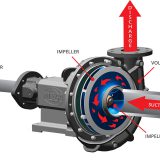

At the point when introducing a clean pump, it is absolutely critical to permit 4-6 tube distances across of straight bay tubing into the pump. This consistent length of bay takes into consideration laminar stream to form into the pump. By anticipating wild, turbulent stream which extraordinarily builds air entrainment in an item we diminish the danger of pump cavitation. As we’ve examined previously, cavitation is an enemy of pump effectiveness in both clean divergent and sanitary pump applications. We have comparable suggestions for stream meters- simply recall, the smoother the stream, the fewer moves, the better the execution.

Help

Here’s an evident one we’ve touched on in past posts- channeling backing. At the point when the clean tubing is brimming with liquid, it might be really substantial. Ten feet of 3″ sterile tube can hold around 4 gallons of liquid. Taking into account water, that is around 33 pounds. That is a great deal of weight to hang off the end of the pump. It’s essential that we circulate this weight and strain autonomously of the pump through the utilization of hooks or different backings. The utilization of pegs will likewise prove to be useful for some of our different tips also. The majority of this weight can result in misalignment of the engine and pump shafts. This can prompt shaft diversion and calamitous pump disappointment. Overabundance strain can likewise bargain framework seals, permit air into the methodology.

Incline

Channeling incline is essential in a sterile framework for a couple of reasons. The primary is to help frameworks channel when we run a cleaning cycle. The second is to forestall air pockets in the suction line. Once more, blending of liquid and air can prompt pump cavitation and a loss of effectiveness. Therefore, while even lengths are satisfactory, it’s critical to minimize line high focuses where air can amass and to incline to channel upward around the delta of the pump.

Strainers and Traps

Strainers and traps not just ensure the item, they additionally secure the pump. Delta side strainers and traps might be utilized to keep pump harm from remote matter. At the point when tagging a mag trap or strainer for the pump gulf, be mindful of stopping up or limiting the pump bay can result in cavitation and stream stoppage.

Weight Gages

As we’ve discussed in past posts channel and release gages are useful in recognizing and diagnosing pump issues. Gages are the most effortless approach to recognize changes in pump, item, or framework condition. See our post in pump weight gages for all the more on this.