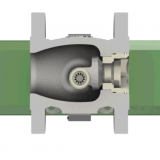

The clamp type check valve is a kind of universal one-way fluid valve. Its weight is light, size is small. It is easy to be installed between flanges. The inner part of the valve consists of two semi-circular springs and a plate, with a pin fixed to the valve body. The spring deformation makes the valve plate closed, while the fluid pressure makes the valve plate open. The spring deformation is quick, which can protect the pipeline from the damage of water hammer.

Installation precautions: when placing the pipe, make sure that the passing direction of clamp type sanitary check valve is the same as that of the fluid flow direction. And it should be installed in vertically placed pipelines. For horizontally placed pipelines, place clamp type check valve vertically. Put a telescopic tube between clamp type check valve and sanitary butterfly valve. Never connect it directly to other valves within the operating radius of the valve plate. Avoid adding pipe fittings and obstructive materials. Don’t install a reamer at the front or rear end of clamp type check valve. When installing a clamp type check valve near the bend, keep in mind that there should be enough space. When installing a clamp type check valve at the pump outlet, leave space at least six times the valve’s diameter to ensure that the butterfly plate is eventually affected by the fluid.