If you are buying sanitary Pumps, there is everything you need to know about sanitary pumps.

The sanitary pump is a kind of classification of pumps in use, which involves the transportation of all products with human contacts, such as pharmaceutical, dairy, beverage, food, cosmetic, food additive, fine chemical and so on.

What are the types of Sanitary Pumps?

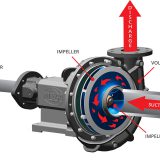

There are four basic types of sanitary pumps: centrifugal, volumetric, jet and airlift. Centrifugal pumps use centrifugal force to generate speed and use rotating impeller to increase speed and push fluid through the outlet valve. Positive displacement pumps use rollers, gears, or impellers to move fluid into a fixed cavity so that when liquid exists, the vacuum that is created draws in more fluid. Jet pumps force fluid through a nozzle, converting the fluid’s energy into velocity energy. Airlift pumps mix air or gas with the liquid media so that the air-liquid mixture, with a lower specific weight than the liquid, rises in the pipe and is discharged above the level of the liquid.

What are the Characteristics of Sanitary Pumps?

There is no blind Angle in the flow

In the food production process, the medium in contact with the pump needs to be flowing. However, the mechanical seal cavity in the normal pump is usually a dead Angle, and the open or conical seal cavity is required.

Weld surface roughness

The surface roughness of the weld shall be 3.2, and the general surface shall be 0.8, that is to say, the pump body flow channel and the impeller flow channel need to be polished. It is difficult for ordinary cast parts to meet this requirement, so the centrifugal sanitary pump generally adopts the stamping and welding structure. Sometimes, the impeller is open or half-open.

Meet the CIP requirements

Most production lines need to be flushed once a day to remove residue that can deteriorate and cause bacteria, while many use clean water for a period of pumping or backwashing. In a flush time period, the slow flow of the medium (such as the sealing cavity of the material) should all flow out.

What are the materials of sanitary pumps?

Generally, the sanitary pump body is made of the material such as metal or plastic. These metals are widely used to make sanitary pumps such as bronze, brass, copper, ductile iron, steel, stainless steel or cast iron. While the plastic choices consist of PVC and CPVC, sanitary pump actuation are variable with different types such as pneumatic, electric, hydraulic as well as manual. The most common connections include socket-weld, butt-weld, threaded, grooved end, thrust, flange, seamless flange and mechanical seal.

What are the benefits of applying sanitary pumps?

An advantage of these pumps is that the parts that come in contact with the liquids are made of stainless steel. The pump can easily be disassembled for sterilization or cleaning. Pump components such as bearings and seals are less vulnerable to wear due to friction. This means that apart from some unique components that may require replacement or repair, they usually require less maintenance. Their high-end components and simplicity of design minimize maintenance requirements.

In addition to their innovative design, the pumps are very competitive. Their quality is unassailable as they are considered one of the most modern pumps on the market.

The operation of the pump produces very low noise levels. This makes it ideal for environments that require minimal disruption.

How to Install Sanitary Pumps?

The following are the factors to consider when installing sanitary pumps:

Straight Lengths of tubes

It is of great importance to have 4-6 tube diameters of inlet tubing that is straight into the pump when installing a sanitary pump. The continuous length of inlet enables the flow to be laminar into the pump. Preventing turbulent, choppy flow increases air entrainment. This further reduces the chances of pump cavitation.

Piping Support

Sanitary tubing becomes very heavy when filled with fluid. 10 feet of 3” sanitary pipe holds about 4 gallons of fluid, in this example, water. That totals up to a weight of about 33 pounds. Such a weight is too much to hang off the pump’s end. Distribution of the weight and strain evenly is therefore necessary. This is done using hangers or other means of support. This weight can misalign the pump shafts and the motor. The result is a shaft deflection and a terrible pump failure. Excessive strain can break the seals in the system and allow air into the process.

Piping Slope

There are three reasons why piping slope is important. First of all, it helps in the drainage of the systems when a cleaning cycle is run. Secondly, it prevents pockets of air in the suction line. Lastly, when fluid mixes with air, it leads to cavitation and loss efficiency of the pump. It is therefore important to slope piping in an upward manner on the inlet side of the pump, and reduce points where air can accumulate.

Strainers and Traps

Strainers and traps protect both the pump and the product. Inlet side traps and strainers can prevent damage to pump by foreign matter. Clogging of the pump inlet can lead to flow stoppage and cavitation.

Pressure Gauges

• Check or foot valves – are located on the inlet. They ensure the maintenance of a liquid leg on the side of the pump that sucks. Sanitary check valves prevent backflow and keep the pump primed.

• Relief valves – protect the piping system from excessive pressure

• Isolation valves – allows for the safe removal of the pump from the piping system and maintenance of the system without having to empty the entire pipeline.

How to maintain sanitary pumps?

The review of sanitary pump repair records and MTBF is of great importance to responsible and conscientious pump users. For convenience, these failure statistics are often translated into MTBF (in this case, the installed lifetime before the failure).

Keep in mind the potential value of choosing pumps that are more expensive initially, but last much longer between repairs. The MTBF of a better pump can be one to four years longer than that of its unimproved counterpart. Consider that the published average values of avoided pump failures range from US $ 2,600 to US $ 12,000. This does not include opportunity costs lost.

For more information, please visit http://www.adamantvalves.com/