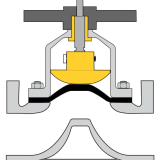

Sanitary diaphragm valves are constructed in a very different form from normal valves, which rely on soft rubber or plastic film to control fluid movement. Commonly used diaphragm valve material is divided into cast-iron diaphragm valve, cast steel diaphragm valve, stainless steel diaphragm valve, and a plastic diaphragm valve.

In sterile manufacturing processes, the most commonly used is the diaphragm type stop valve, which is commonly referred to as the sanitary diaphragm valve. Diaphragm valves are used in aseptic manufacturing processes because they are simple in structure and cheap in price, which leaves it with few competitors so far. The only thing that can compete with diaphragm valves is the so-called bellows tube valve, commonly known as the bellows valve. The bellows valve is too expensive to compete with the diaphragm valve despite its technical advantages.

In the aseptic process industry, the competition between the bellows valve and sanitary diaphragm valves has a long history. For a long time, the diaphragm valve occupies the advantages with its simple structure, low price and convenient cleaning and disinfection. Compared with diaphragm valves, bellows valves are of limited specification on the market.

When a sanitary diaphragm valve is required in a horizontal pipe, it must be guaranteed to be installed in the horizontal pipe at the angle specified by the manufacturer of the diaphragm valve. Otherwise, there will be some problems with the diaphragm valve emptying during the operation of the process equipment. However, there are different types of diaphragm valves, diaphragm valves manufactured by different manufacturers and diaphragm valves with different nominal flow rates, which often bring great trouble to the design and manufacture of sterile process equipment. The problem of emptying the body is even more apparent in the T-shaped diaphragm valve.

No matter what the body of the bellows valve is, there will be no dead angle during no-load operation of the process equipment, thus ensuring the strict separation of the pipe. Furthermore, it can be installed in the piping system of sterile process equipment in different ways.

In the pharmaceutical industry, aseptic process equipment consists of many horizontal and vertical pipes. In the design of pharmaceutical equipment, such bellows valves must be installed in specific locations for piping and technical reasons. For example, if the diaphragm valve is installed in the vertical pipe, there shall be a 90 ° bend pipe connection in the same horizontal plane, so the T-shaped diaphragm valve has a high production cost. Compared with diaphragm valves of different body shapes, bellows valves are more advantageous in volume and shape and in connection with the pipe. Due to the different structure types of the two types of globe valves, we should choose which type of globe valves should be used in each part in the early stage of sterile process equipment design.

Adamantvalves supplies all kinds of high-quality valves such as sanitary butterfly valves, sanitary ball valves, sanitary diaphragm valves, sanitary shut off valve, etc. Please visit http://www.adamantvalves.com/ for more information.