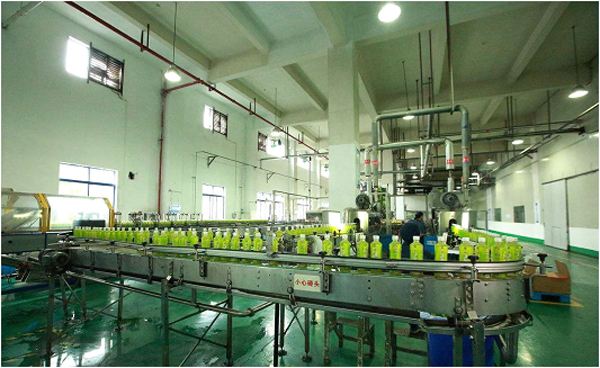

Changes are bound to occur in food processing plants, especially as a result of recent happenings. Food recalls are being made every year, workers are becoming scarcer and production costs just have to be pushed down for sustainable production.

Sustainable production is not just about workers and creating jobs but more about efficiency. More work needs to get done with current resources and with time the machinery used will change. The first step is the maintenance of sanitary conditions.

The product recalls put a lot of doubt among consumers about processed foods and without the consumer’s trust in the different brands, minimal sales will be made. A clean and sterile environment and sanitary 3 way ball valve will ensure that bacteria are kept out of the processing plant thus ensuring safer food for the consumer.

Staff uniforms and protective gear are also already being provided by different plants so as to ensure everything used while in the plant is sterile. This is actually better for employees since they don’t have to worry about getting the right uniform and making it sanitary enough for the plant.

Since employees are fewer their welfare will be handled better. Basic and dirty locker rooms should be a thing of the past with employees having nicer facilities to work and change. A worker in a better working environment should be able to produce better and meet targets.

Workers run the activities in plants but since the numbers of workers are slowly dwindling machinery will do the job. Current machines do a lot of packaging and sealing work but newer machines should actually be able to do what a human does. In poultry plants, the machines being developed will be able to debone chicken with precision just like the human hand. A visual ability should be incorporated into the machine for this to be possible and it is still being worked on, including having just enough strength to slice through the poultry but not shatter the bone.

Machines take up to eight hours to clean which takes away time and manpower from other production activities and increases the amount paid out in wages. Newer machines being developed will have a design that makes them easier to clean (around one hour) and some will even be able to self-clean.

Energy is a constant source of worry since when one power line goes down the whole plant remains inactive. Most companies are opting to spread their plants over different sites so as to maintain production. Energy-saving techniques, such as variable frequency drives and refrigerant heat harvesting, are also being employed to ensure maximum efficiency.

The wise companies will definitely look into such tactics to minimize production costs so as to maintain sustainable production.

For more information, please visit http://www.adamantvalves.com/