A Sanitary ball valve is a multi-turn ball valve, which uses the principle of tilt and rotation to eliminate the sealing surface abrasions. When the valve is closed, the ball core is by mechanical force wedge to the sealing seat, without relying on the help of differential pressure can ensure a tight seal; when the valve opens, the ball core from the seat, the pipeline along with the ball fluid.

The main characteristics of sanitary ball valves are low flow resistance; stainless steel flanged ball valves can be fully sealed under higher pressure and temperature;

The hygienic ball valve can be opened and closed quickly. The hygienic manual ball valve body is symmetrical, can effectively withstand pipeline pressure, can cope with various high-pressure vacuum conditions, and has a wide range of applications.

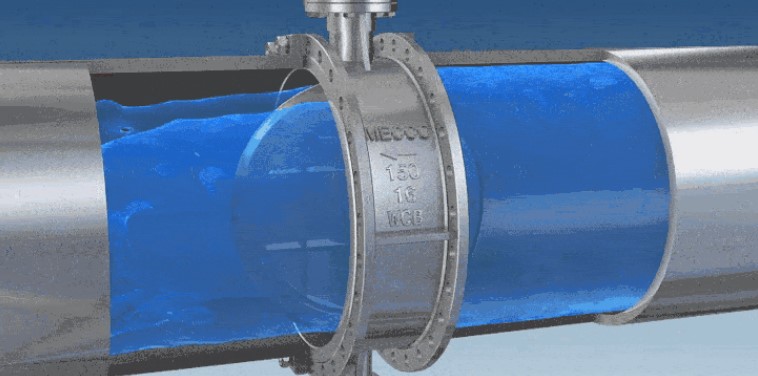

A hygienic manual butterfly valve was installed in the pipe diameter direction. In the butterfly valve body cylindrical pass inside, the center of the disc-shaped butterfly plate around the axis can be rotated between zero to ninety degrees, when the valve flaps to ninety degrees, the sanitary valve is in a full-open state, we can directly see the shape of the butterfly valve and can also easily understand the working principle.

The opening and closing parts of hygienic butterfly valve are disc-type. The main characteristics are as follows:

1. It is simple in structure, small in volume, and convenient in installation.

2. The flow resistance coefficient is small and the opening and closing are fast.

3. It can be used for large-caliber valves, different sealing surfaces, and various environments, including powder and pull media. Relatively speaking, the sealing of sanitary ball valves is better.

What are the characteristics of a hygienic pneumatic butterfly valve?

1. Hygienic pneumatic butterfly valve is simple, small in size, light in weight, small in flow resistance, large in flow coefficient, and good in sealing performance. The regulation range is large. It is the executive unit of the instrument in the automatic control system.

2, the sanitary pneumatic butterfly valve adopts the electric pneumatic valve positioner. With the electric signal and compressed air as the power, it receives the 4-20mA DC current signal input by the control system. The regulator converts compressed air into the gas source pressure signal input and output, changes the rotation angle of the valve plate, and has better adjusting and controlling the flow rate and other parameters.

For more information, please visit http://www.adamantvalves.com/