The sanitary check valve is possibly the only best valve which can be used in your plant that can be operated without receiving any external assistance or giving any indication about the setting or about the condition. The special quality made the valve unique in the valve industry. Thus anyone can instigate to realize that this kind of valve is one apart from the rest.

The selection as well as application of sanitary check valves is all about an art. From The latest developments you can understand the fact that how necessary it is on the part of the valve designer to know completely the mechanism inside the valve. Nevertheless the user should go even farther and figure out all the influence external to the valve. To proceed further it is necessary to keep a record of what has succeeded or failed during the process. This is the reason why all the plants and installation work use check valves. Moreover for some plants it saves the piping cost. To select and evaluate check valves, It is necessary to know the basic forces and conditions influence the valves. Some common aspects like temperature, fluid, pressure, and outside materials factors are the condition influence the working of the valve.

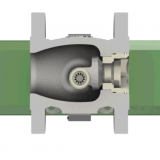

The upstream pressure of the fluid Force the valve to open. comes from itself. A few weak and Sudden application may sometime cause a trouble. The time while the valve is open, fluid turbulence and vorticity make the valve internals vibrate or spin in order to wear and break them. These wear can be far worse than the wear from thousands of cycles of openings and closings. Thus ultimately, the backflow and sudden closure can create water hammer and even wreck the valve. galling, fatigue cracks, plastic yield, and fracture often occur in extremely demanding service.