Check valve is to rely on the media itself to flow and automatically open and close, to prevent the back flow of the media, also known as reversing valve, and back pressure valve.

Check valve is an automatic valve, its main role is to prevent the media back, to prevent the pump and drive motor reversal, as well as the release of the container medium. The check valve can also be used to provide a supply of pressure which may rise to more than the pressure of the system.

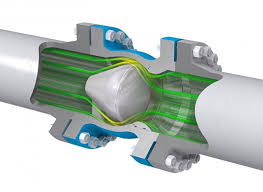

Check valve can be divided into swing check valve and lift check valve. The role of this type of valve is only allowing the media to flow in one direction, and stop the flow direction. Usually the valve is automatically work, fluid pressure flow in one direction, the valve open; the opposite direction of fluid flow by gravity, fluid pressure and valve closing has effect on the valve seat, thereby cutting off flow.

The check valve belongs to this type of valve, which includes swing check valves and lift check valves. Swing check valve has a hinge mechanism. In order to ensure that the valve flap can reach the appropriate position of the valve seat every time, the valve flap design in the hinge mechanism, so that the valve flap is sufficient to have a swing space, and make the valve really comprehensively contact with the valve seat.

Valve can be all made of metal, can also be placed on the metal leather, rubber, or synthetic coverage, depending on the performance requirements. Swing check valve is in the fully open condition, the fluid pressure is almost unimpeded, so the pressure drop through the valve is relatively small. Lift check valve is located on the valve seat sealing surface. In addition to this valve disc is free to lift, like the rest of the cut-off valve, the fluid pressure valve from the valve seat sealing surface lift, medium return led down to the valve seat, and cut off the flow. According to the conditions of use, the valve flap can be all metal structure, you can also be on the valve frame mounted rubber pad or rubber ring form.

The same as the cut-off valve, lift check valve fluid through the channel is narrow, so the check valve by lifting the pressure drop than the swing check valve a little bigger, and swing check valve flow restrictions very little.

According to its structure and installation, check valve can be divided:

One, swing check valve: swing check valve to the disc valve seat is rotated around the channel axis, because the valve channel is streamlined, but not for the pulsating flow, the sealing performance is less than lift. Swing check valve is divided into single, double valve, the main form of these three points to the valve diameter, the purpose is to prevent the media to stop the flow or back, weakening the hydraulic impact.

Two, lift check valve: the valve flap is along the vertical centerline of the valve sliding check valve, lift check valve can only be installed in the horizontal pipe, small bore check valve can be used on the high-pressure ball. The body of the lift check valve is the same as the globe valve, so that the fluid resistance coefficient is larger. The structure is similar to the cut-off valve, the valve body and disc with the same cut-off valve. The lower part of the upper valve and the valve cover processing guide sleeve, the valve has free guide simple light driven, when the medium is downstream, the valve thrust is opened by the media, when the media stopped flow, the valve is vertical landing on the seat, preventing the media from the upstream effect. Straight through lift check valve direction of medium inlet and outlet channel direction is perpendicular to the seat; vertical lift check valve, the media import and export channel in the same direction with the valve seat, the flow resistance is small.

Three, disc check valve: the valve seat is rotated around the valve pin. Disc check valve structure is simple, can only be installed in the horizontal pipe, poor sealing.