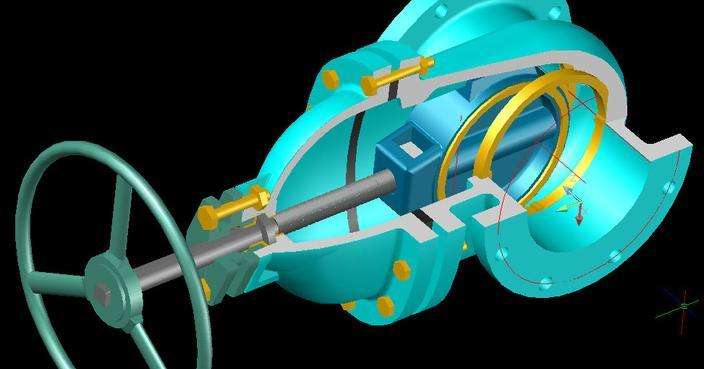

Gate valve realizes switching from open to close by the external force and realizes the flow between media. Because the resistance of the flow is very small, the directly connected medium in the internal passage flows in a straight line, so the resistance will be very small, and it will be more labor-saving after starting. It is vertical to the medium material. The longer the time, the friction will occur, which will affect the sealing performance between the flow. So, how to install and maintain gate valves?

Attention should be paid to the installation and maintenance of gate valve: Handwheel, handle and the transmission mechanism are not allowed to be hoisted, and collision is strictly prohibited. Double gate valves shall be installed vertically.

Gate valves with belt drive mechanism shall be installed in accordance with the specifications of the product. If the valve is often switched on and off, lubricate it at least once a month. The gate valve is used as a cut-off medium. When it is fully open, the whole flow is through, and the pressure loss of medium operation is minimized.

Gate valves are usually suitable for working conditions that do not require frequent opening and closing and keep the gate fully open or closed. It is not suitable for regulating or throttling.

For the high-speed flow medium, the gate vibration can be caused by the partial opening of the gate, and the vibration may damage the sealing surface of the gate and the seat, and the throttling will cause the gate to be eroded by the medium. From the structural form, the main difference is the form of sealing elements used. According to the form of sealing elements, gate valves are often divided into several different types, such as wedge gate valves, parallel gate valves, parallel double gate valves, wedge double gate valves and so on. The most commonly used forms are wedge gate valves and parallel gate valves.

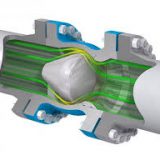

The function of this type of valve is to allow the medium to flow in only one direction and to prevent the flow in the direction. Usually, the valve operates automatically, and the disc opens under the action of a fluid pressure flowing in one direction. Check valves belong to this type of sanitary valves, which include swing check valves and lift check valves.

Swing sanitary check valves have an intermediate hinge mechanism and a door-like disc that is free to rest on the inclined seat surface. In order to ensure that the disc can reach the proper position of the seat surface every time, the disc is designed in a hinge mechanism so that the disc has sufficient swing space and makes the disc truly and comprehensively contact with the seat.

Valve discs can be made entirely of metal or can be metal inlaid with leather, rubber, or synthetic coverage, depending on the performance requirements. When the swing check valve is fully opened, the fluid pressure is almost unimpeded, so the pressure drop through the valve is relatively small.

The disc of the lift sanitary check valve is located on the sealing surface of the seat on the valve body. In addition to the valve disc can rise and fall freely, the rest of the valve is like a globe valve. The fluid pressure causes the disc to rise from the seating surface, and the medium reflux causes the disc to fall back to the seat and cut off the flow.

According to service conditions, the disc can be all-metal structure, or it can be in the form of rubber pads or rubber rings embedded on the disc rack. Like globe valves, the passage through which fluid passes through the lift check valve is narrow, so the pressure drop through the lift check valve is larger than that through the swing check valve, and the flow of the swing check valve is limited very little.

For more information, please visit http://www.adamantvalves.com/products.html